[22 November 2023] – The renowned companies Eisenbacher Dentalwaren and Eplus3D are delighted to announce the successful completion of an important development project for the industry. This project has demonstrated that Eisenbacher Dentalwaren's KeraS metal powder can be processed on Eplus3D's metal 3D printers to produce dental frameworks with the highest component quality that meets the strict requirements of DIN EN ISO 22674 for type 5 alloys.

The partnership between Eisenbacher Dentalwaren and Eplus3D represents a significant milestone in the dental industry. Dental laboratories worldwide can now benefit from the best-in-class combination of KeraS metal powder and advanced 3D printers from Eplus3D to manufacture high-quality and precise dental prostheses, crowns, bridges, and implants.

The collaboration between the two companies comes at a critical time, as all dental laboratories in the EU must comply with the requirements of the Medical Device Regulation (MDR). The certification of the printing process is becoming a fundamental requirement for dental laboratories to adhere to the MDR. Eplus3D is actively committed to supporting its existing customers in the dental industry in tackling this significant challenge. For instance, the company collaborates with various manufacturers to validate a range of metal powders from the dental sector, allowing dental laboratories to have access to a wide selection of certified materials. Thanks to the open machine architecture of the Eplus3D systems, customers benefit from a fundamentally wide variety of materials. Together with Eisenbacher, the validation of further alloys is already nearing completion.

Once the process has been implemented by Eplus3D's engineers, the user can regularly produce samples to confirm the functionality of their certified process. Eplus3D and Eisenbacher offer their support in the implementation of the process review.

The partnership between Eisenbacher Dentalwaren and Eplus3D promises a promising future for dental laboratories in Europe and beyond. For further information and inquiries, please do not hesitate to contact the contact persons at both companies.

About Eisenbacher Dentalwaren:

Eisenbacher Dentalwaren is a leading manufacturer of high-quality dental products "Made in Germany." The company offers a wide range of alloys, CAD/CAM discs, and metal laser melting powders and has significantly expanded its presence in the field of additive manufacturing in recent years.

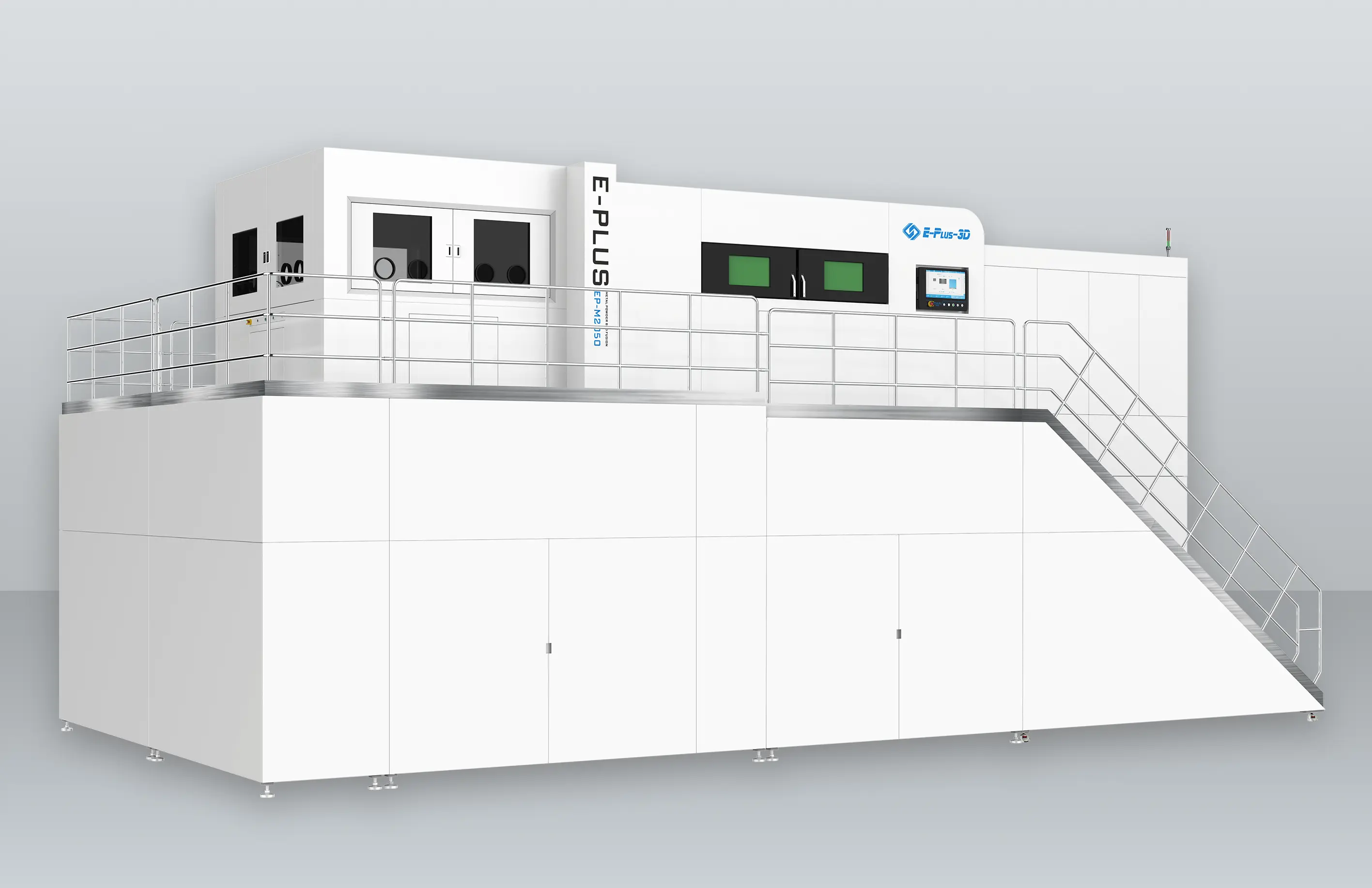

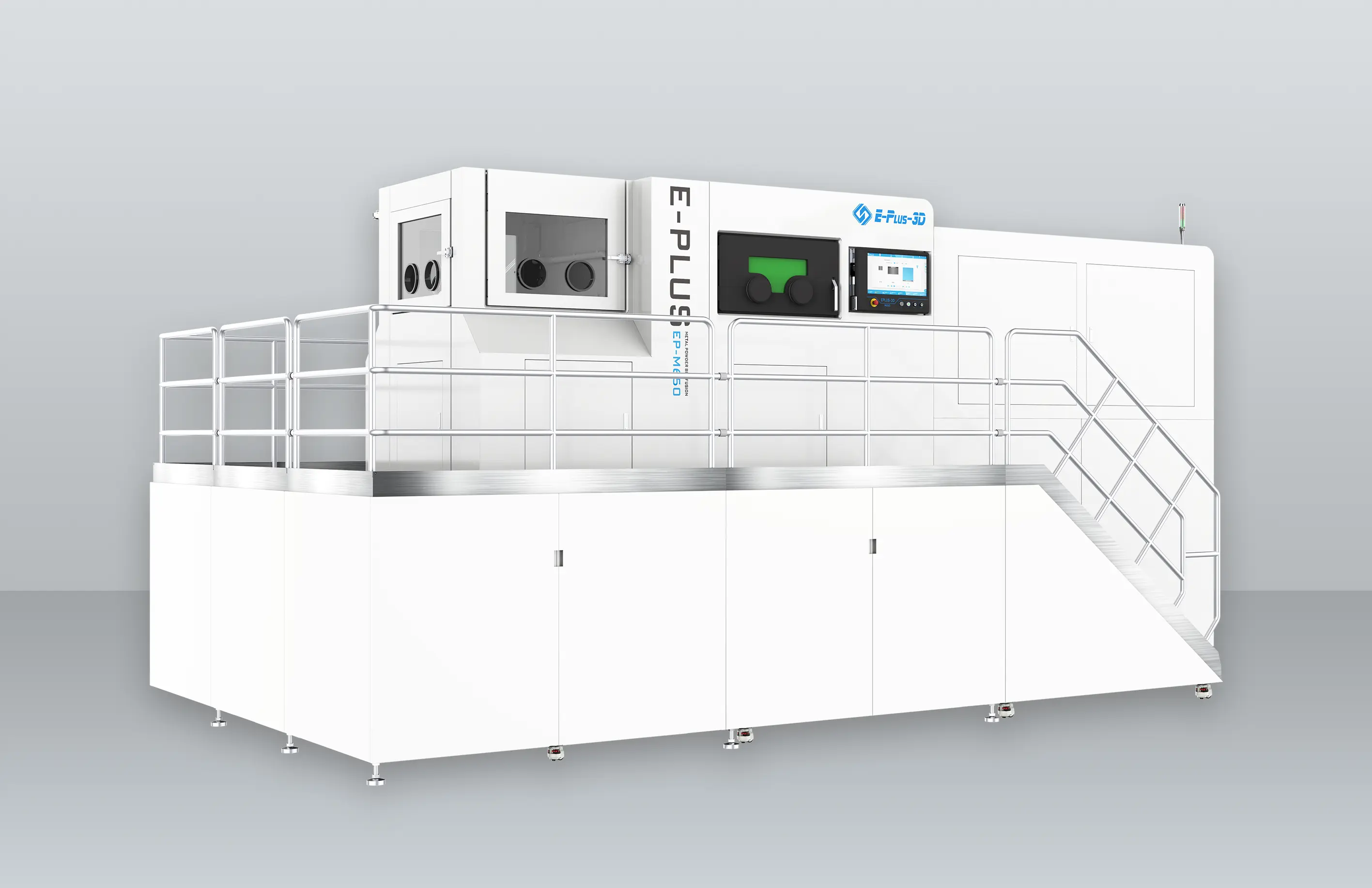

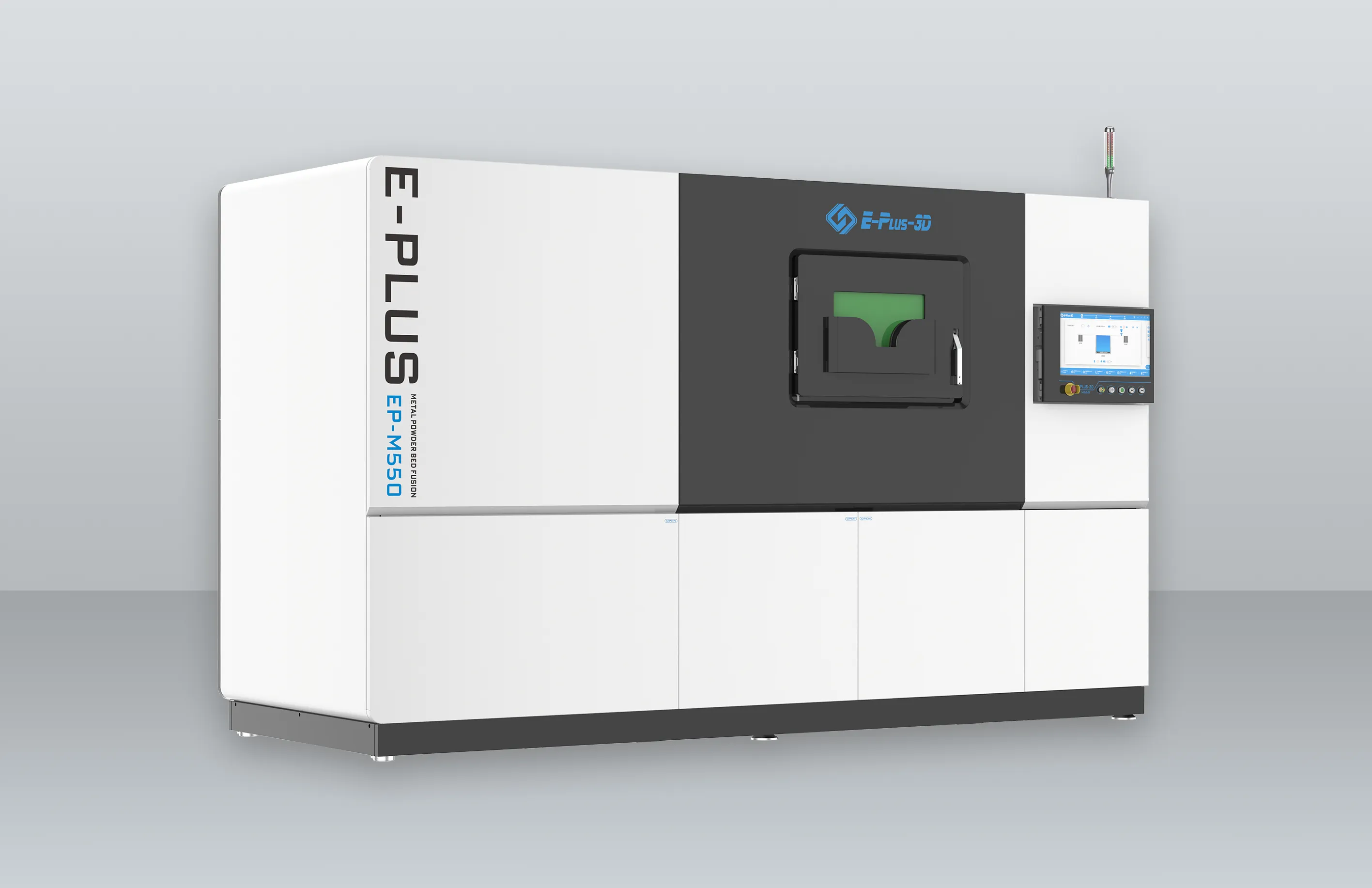

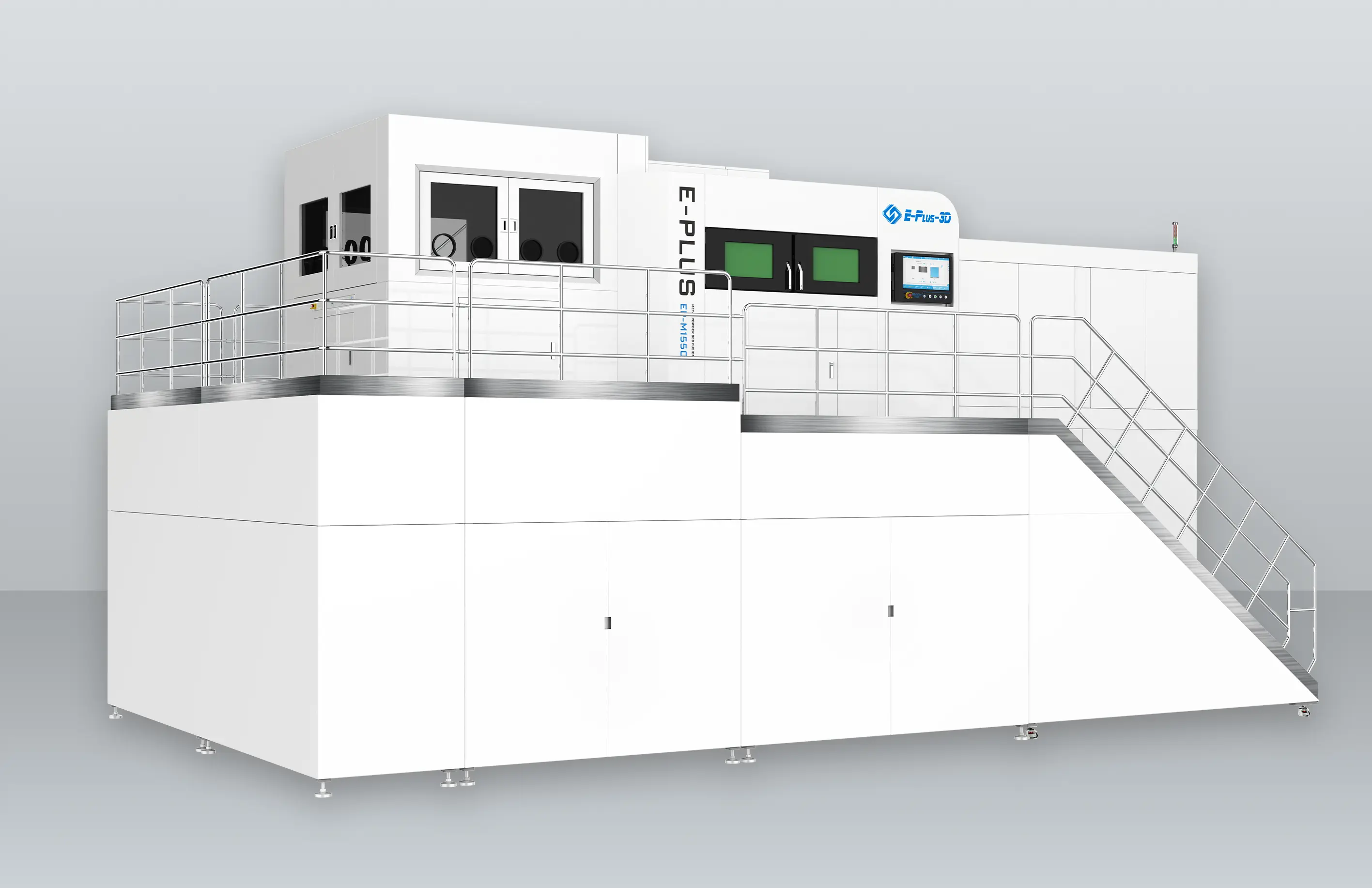

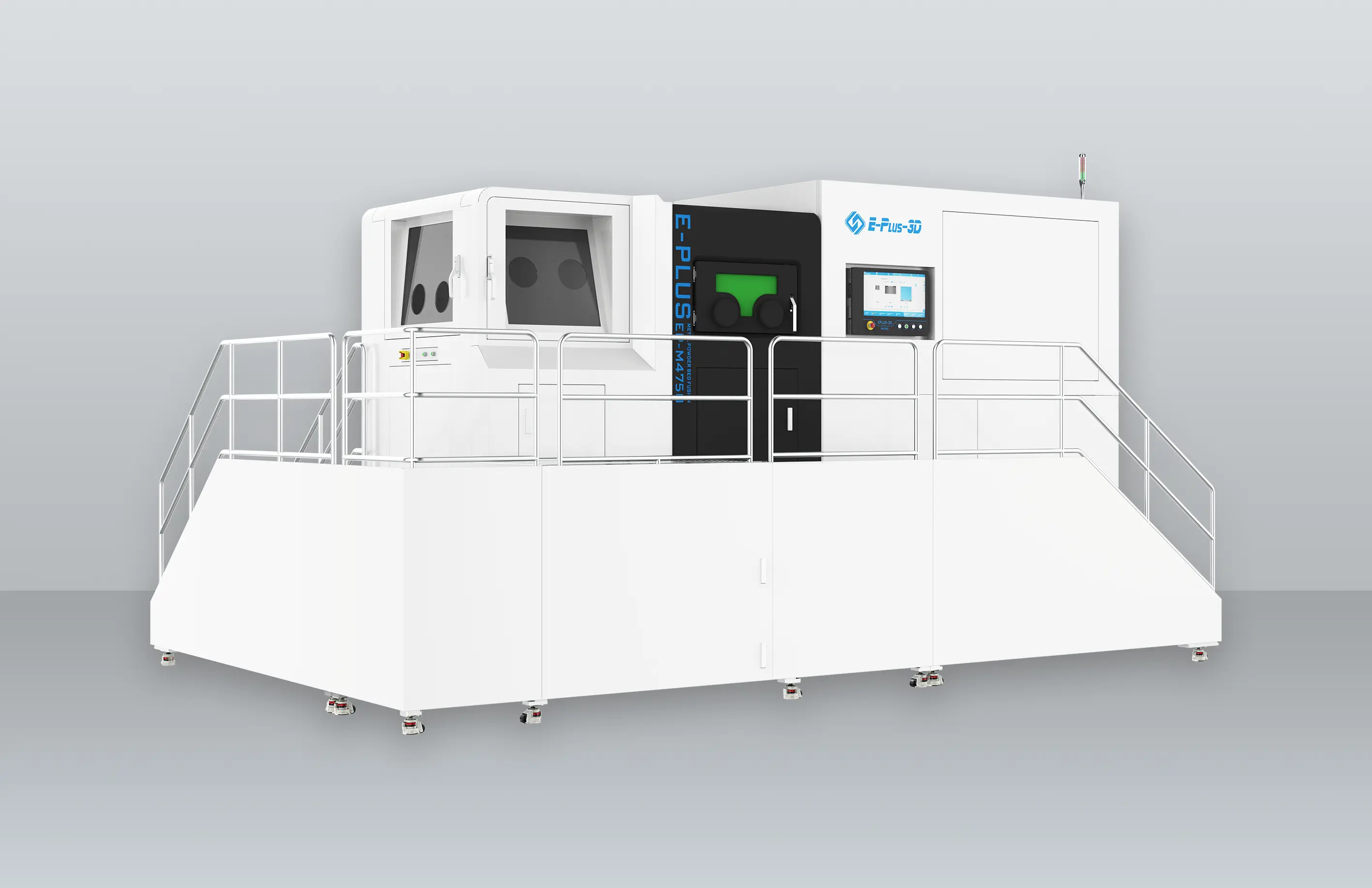

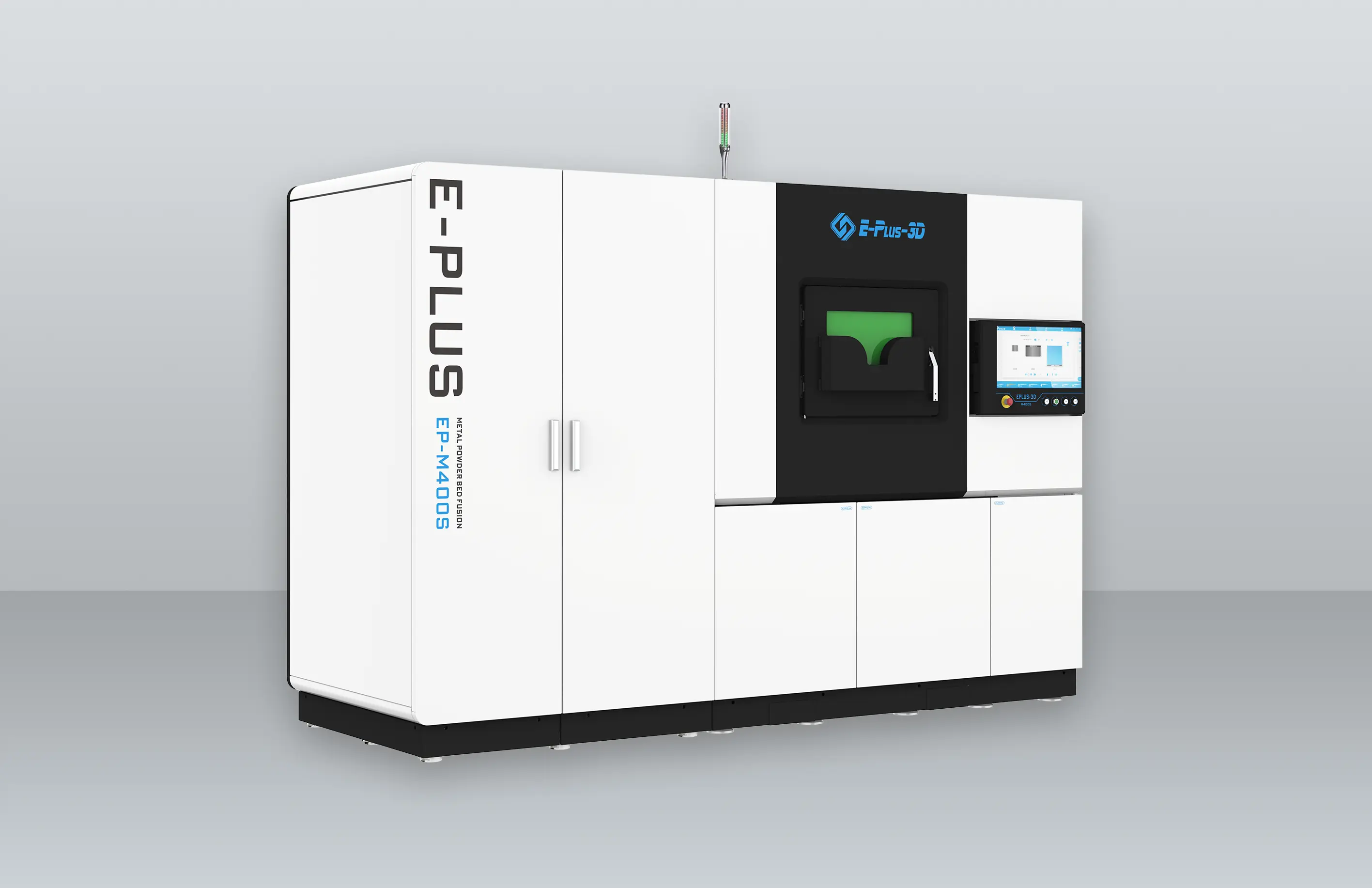

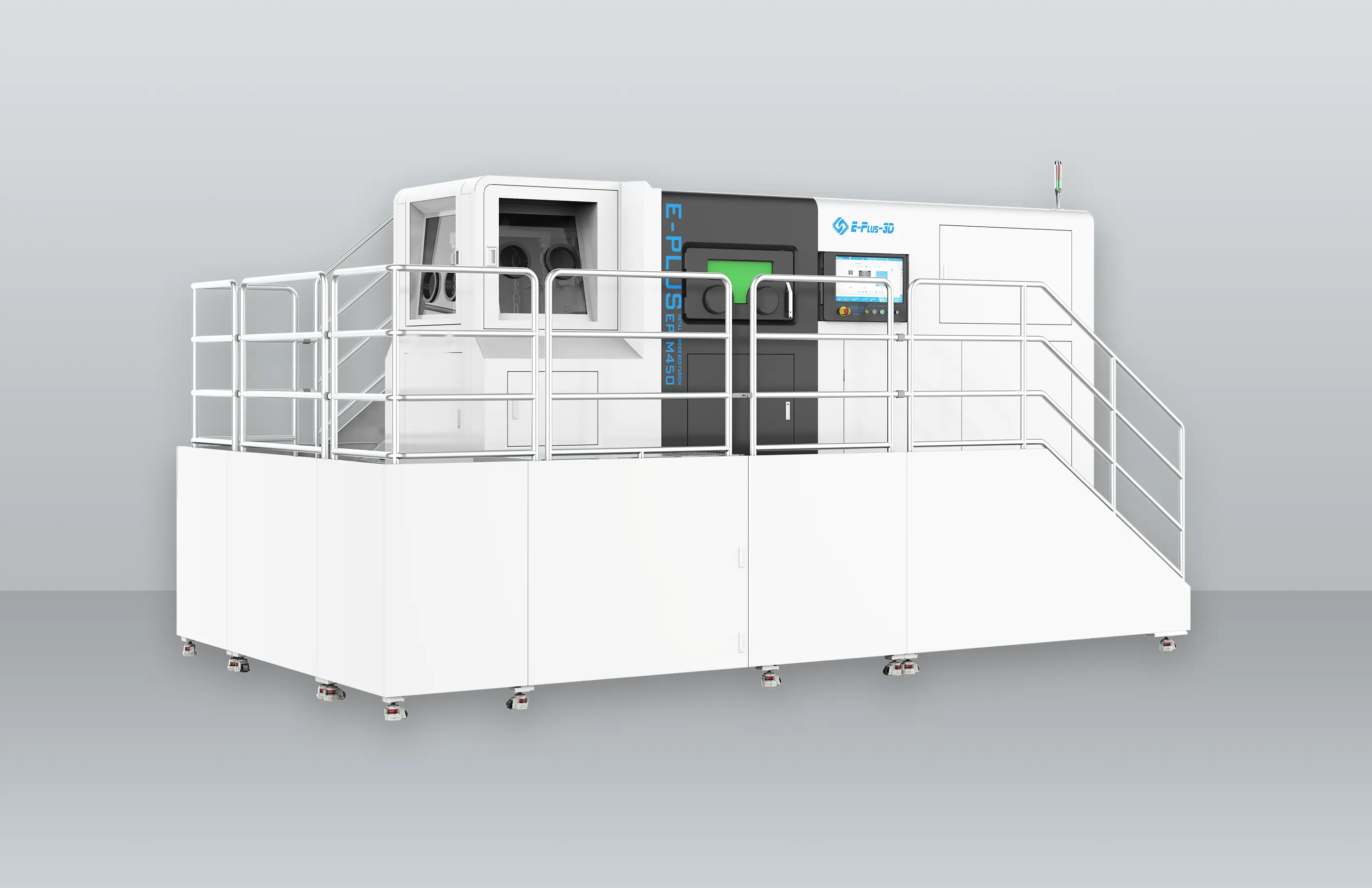

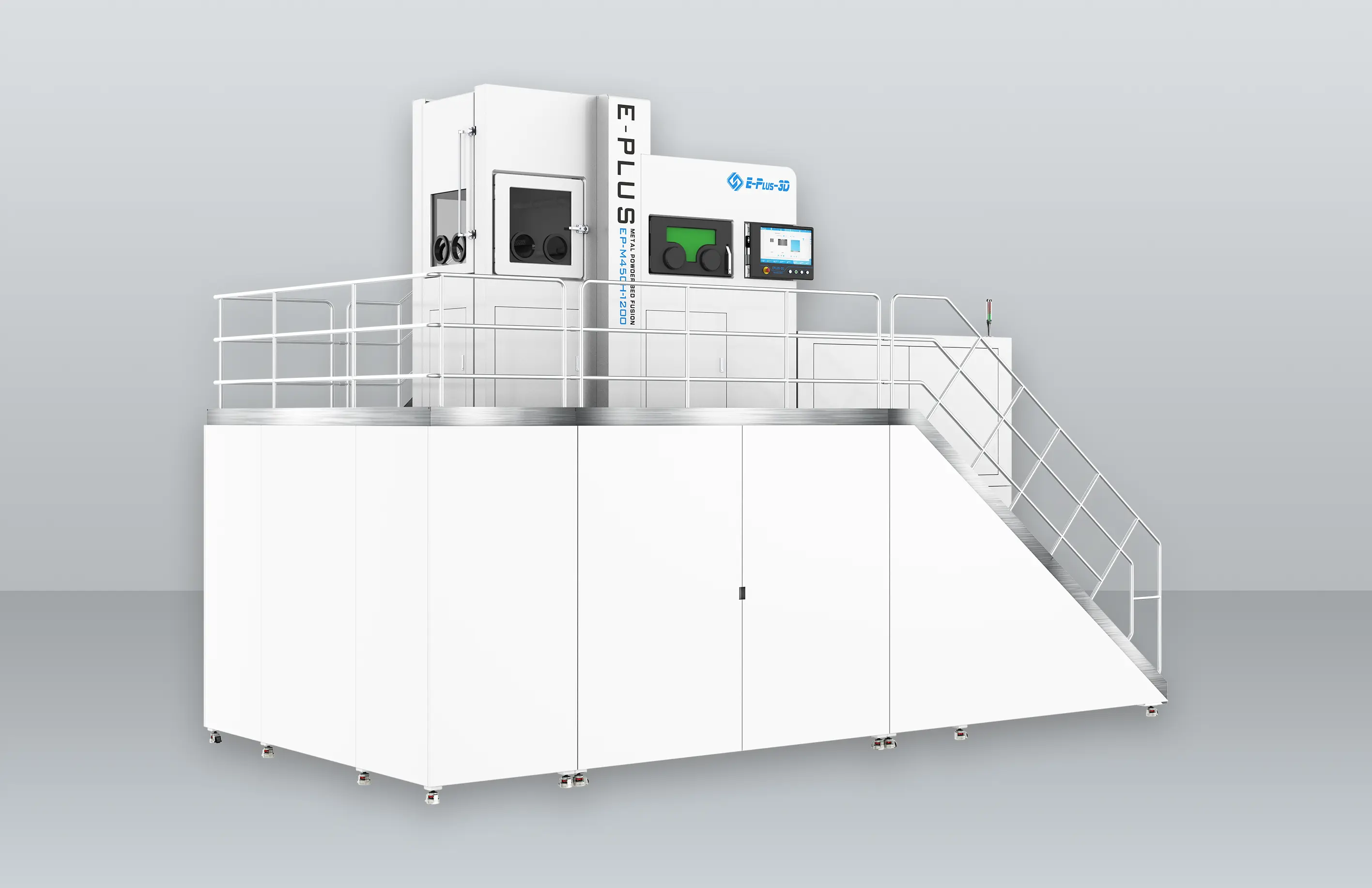

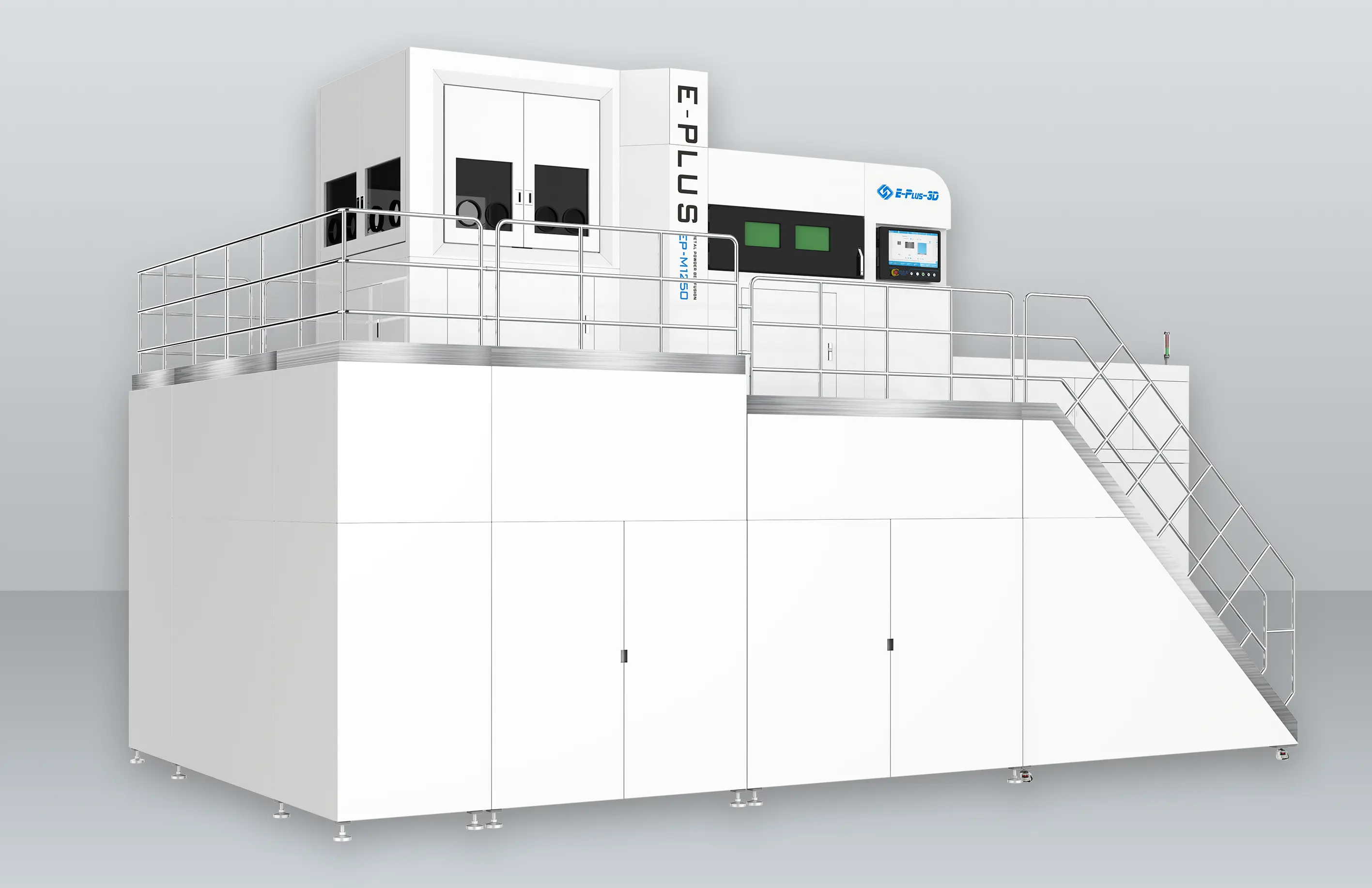

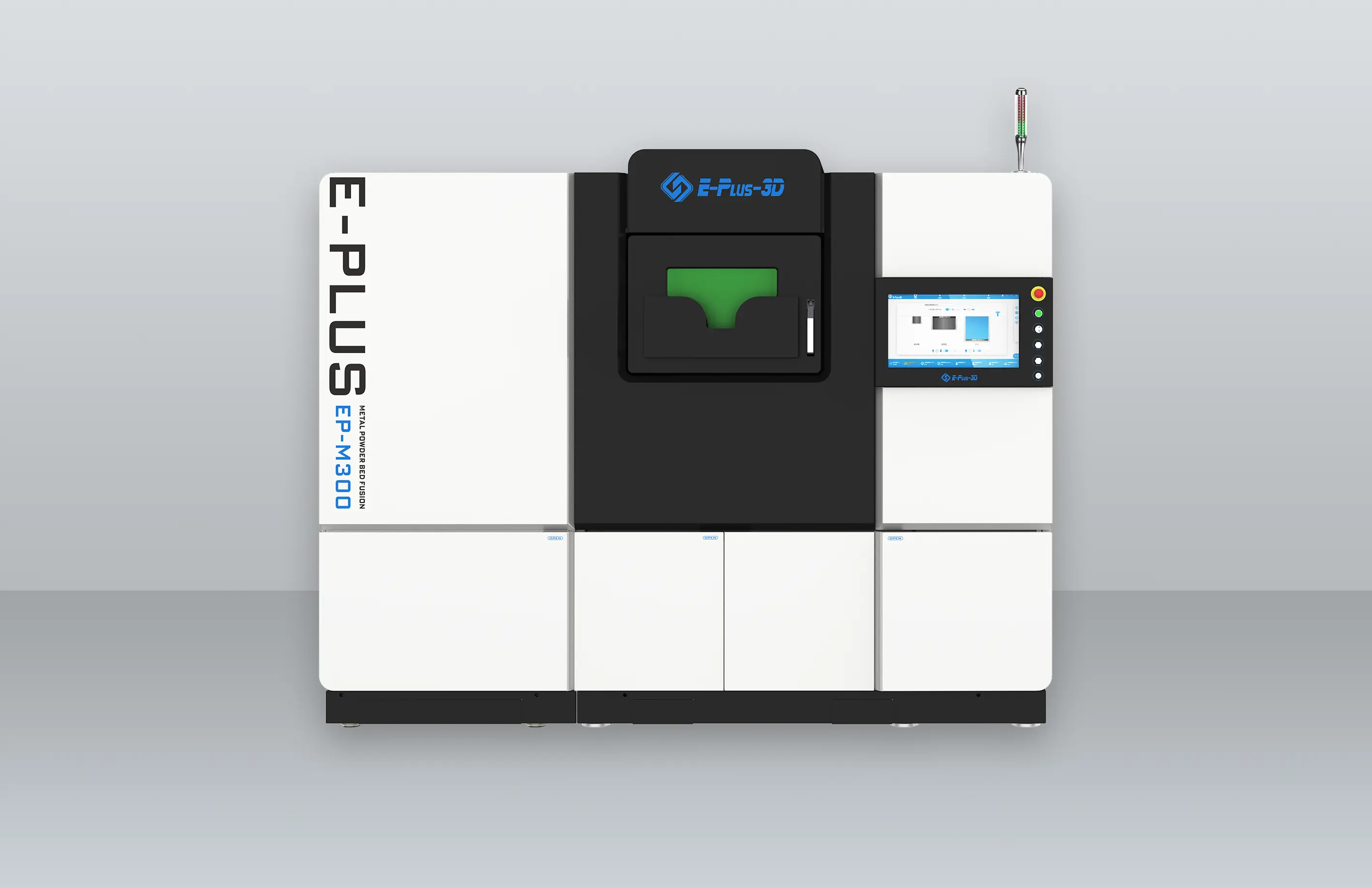

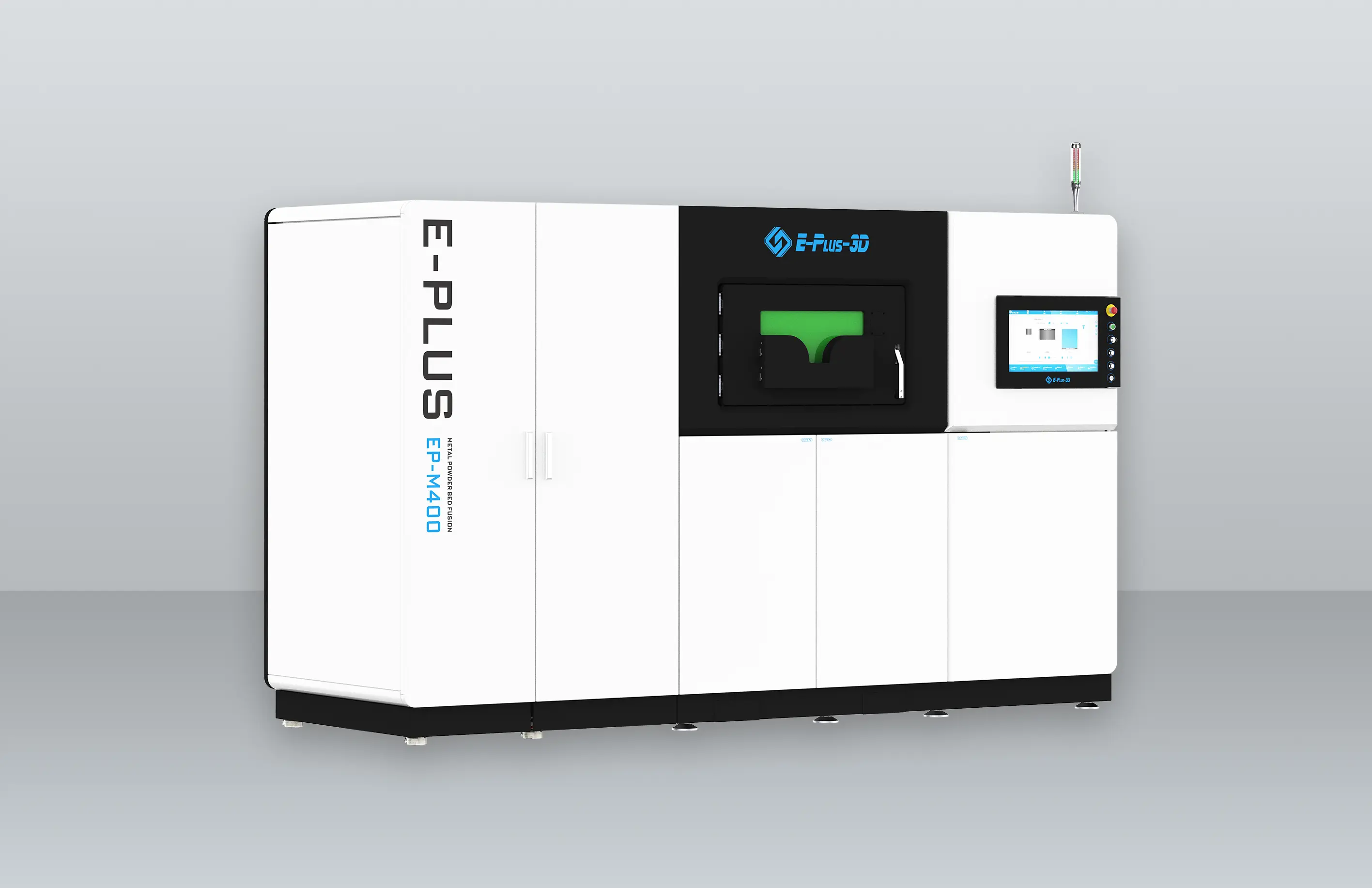

About Eplus3D:

Eplus3D was founded in 2014 and is a leading provider of comprehensive solutions in the field of additive metal 3D printing. With over 80 systems in Europe and extensive expertise in industries such as aerospace, medicine, and mechanical engineering, Eplus3D offers innovative solutions and support to customers worldwide.